Rethinking waste recycling: partnership with Omnivore Recycling

Waste recycling in the sense of the circular economy: from production waste to animal feed and fertilizer for local smallholders

Agriculture in Kenya faces numerous challenges, especially for smallholder farmers who are often faced with high production costs: Feed for chickens and fish accounts for up to 90% of these costs in many cases. Conventional feed is often expensive and is usually made from imported raw materials, which drives up costs for smallholder farmers and at the same time pollutes the environment due to long transportation routes.

LIMBUA and Omnivore Recycling have launched a partnership to develop possible solutions to this problem and at the same time promote sustainable alternatives to soy, maize or fishmeal. By working together, we can directly address two critical needs of Kenyan smallholder farmers: the provision of high-quality, affordable animal feed and organic fertilizer.

How does this work?

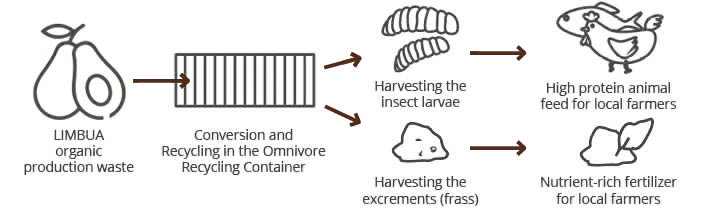

By utilizing organic waste from LIMBUA production through insect larvae from Omnivore Recycling's innovative system. The insect technology is able to recover nutrients and thus provides a source of protein for animal feed.

At the start of the pilot project, the Omnivore Recycling team visits us at our production site in Ena. They learn about the processes involved in avocado, mango and macadamia production and form teams to implement the first container system for waste recycling using insect larvae.

Marius Wenning, founder of Omnivore Recycling, inspects the LIMBUA organic compost - consisting of waste from avocado production, among other things

Risks of conventional animal feed production

Conventional feed production, in particular the use of fishmeal, poses considerable environmental problems. Fishmeal is made from wild-caught fish and is an important source of protein in animal husbandry, particularly in aquaculture.

However, feeding wild fish to farmed fish for food production is not only inherently contradictory but also leads to serious environmental problems, including the depletion of fish stocks in the oceans (including by-catch) and significant CO2 emissions due to transportation and production.

Soya and maize as animal feed for livestock farming lead to deforestation and habitat loss for humans and animals, soil impoverishment and damage to the environment through the intensive use of pesticides and chemical fertilizers, among other problems. Therefore, the use of Omnivore Recycling technology in combination with biological waste can represent an innovative problem-solving strategy.

Waste recycling of production waste: A further step towards a circular economy

At LIMBUA, we have been committed to the sustainable use of our resources from the very beginning. While much of our production waste is already converted into organic compost for the smallholder farmers, the partnership with Omnivore Recycling offers an additional dimension to waste management: by processing our organic waste, consisting of leftovers from organic avocado, macadamia and mango production, we are creating a new way to utilize these resources.

The waste is processed in a scalable container system from Omnivore Recycling, where each unit is equipped with insect larvae and can convert up to 1 ton of organic production waste per day. Over the course of the project, one of these container systems will be installed at our production site in Ena, with additional units added as needed to increase capacity.

It's about more than just recycling; it's about creating a system where resources are reused, reducing the need for new raw materials and minimizing waste.

Conversion of organic waste into animal feed and fertilizer for smallholder farmers

From waste to resource: efficient conversion of organic production waste

The partnership with Omnivore Recycling is based on a multi-stage process that focuses on the larvae of the black soldier fly (BSF) as the main actor. These are the main steps:

Installation of the container system: Omnivore Recycling first installs a specialized container as a pilot project at our production site in Ena. This system can process up to 1 ton of organic waste per day and can be scaled up by adding more containers to increase capacity if needed.

Feeding the organic waste: The leftovers from LIMBUA production are added to the container as a mixture, where they serve as food for the larvae of the black soldier fly. These larvae are known for their ability to break down organic material quickly and efficiently.

Black soldier fly (BSF) larvae - not only chickens appreciate this source of protein

Harvesting the end products: After feeding, the larvae, which now have a high protein content of 40-50%, are harvested. These protein-rich larvae are an excellent feed for chickens and fish, which helps smallholder farmers to reduce the high costs of conventional feed. In addition, frass, a nutrient-rich fertilizer, is produced from the larvae's excrement, which can either be used directly in agriculture or mixed with compost to further increase the nutrient content.

Benefits for smallholder farmers and the environment

The end products of this innovative waste recycling are not only sustainable, but also extremely valuable for local agriculture. The BSF fertilizer improves soil fertility and supports farmers' yields, while the protein-rich insect feed can provide a cost-effective alternative to conventional feed.

A team of LIMBUA employees supports the Omnivore Recycling Team in implementing the container system

Insect protein pilot project - what happens now?

For LIMBUA, this partnership represents an important diversification of our waste management strategies. By working with Omnivore Recycling, we are continuing to minimize the environmental footprint of our production while supporting local agriculture in Kenya. This innovative solution shows how the circular economy can be put into practice and offers a model that could be of interest to other companies and regions.

In the coming weeks, we will monitor the progress of the project and provide first insights into the food recovery and the valuable BSF fertilizer. We look forward to sharing more insights from the journey and providing further updates on the next developments and results of this pilot project.